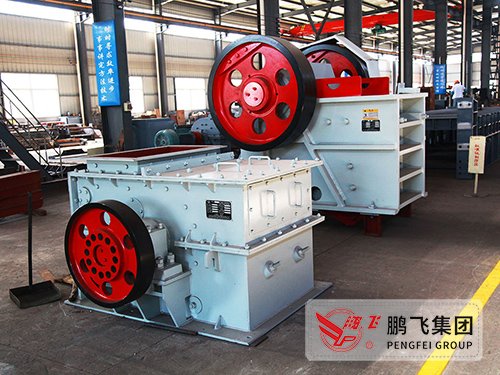

Overview: This series of crushers is mainly used for coarse and medium crushing operations of various ore materials with compressive strength not exceeding 320 megapascals. Has a high fragmentation ratio. The product has the characteristics of uniform particle size, simple structure, reliable operation, easy maintenance, and low operating costs. Widely used in industries such as mining, smelting, building materials, highways, railways, water conservancy, and chemical engineering....

Tel: +86-513-88755311 88755027

The electric motor drives the eccentric shaft to rotate through the pulley, causing the movable jaw to periodically approach and leave the fixed jaw, thereby crushing the material in various ways such as squeezing, rubbing, and rolling, causing the material to gradually fall from large to small and eventually discharged from the discharge port.

1. Rack 2. Fixed jaw plate 3. Active jaw plate 4. Moving the jaw 5. Eccentric shaft 6. Elbow board 7. Adjust the seat

| Model | Maximum feed particle size (mm) | Adjustment range of discharge port (mm) | Processing ability; (m3/h) | Electric motor power (kW) | Weight (excluding motor); (t) |

|---|---|---|---|---|---|

| PE-60× 100 | 45 | 3-10 | 0.2-0.6 | 1.1 | 0.16 |

| PE-150× 250 | 125 | 10-40 | 0.6-3 | 5.5 | 0.81 |

| PE-250× 400 | 210 | 20-80 | 3-13.1 | 15 | 2.8 |

| PE-250× 500 | 210 | 20-80 | 5.7-31 | 18.5 | 3.37 |

| PE-400× 600 | 340 | 40-100 | 10-40 | 30 | 6.5 |

| PE-430× 600 | 400 | 90-140 | 35-60 | 37 | 6.5 |

| PE-475× 1050 | 400 | 90-140 | 37.5-81 | 55 | 11.7 |

| PE-500× 750 | 425 | 50-100 | 28.5-62.5 | 55 | 10.3 |

| PE-550× 900 | 450 | 50-120 | 47-75 | 55 | 7.8 |

| PE-600× 750 | 500 | 150-200 | 50-100 | 55 | 12 |

| PE-600× 900 | 500 | 65-160 | 30-75 | 55-75 | 15.5 |

| PE-620× 900 | 500 | 95-145 | 31-70 | 55-75 | 14.3 |

| PE-670× 900 | 520 | 195-245 | 66-83 | 55-75 | 14.8 |

| PE-720× 900 | 520 | 195-245 | 66-83 | 55-75 | 14.8 |

| PE-750× 1060 | 630 | 80-140 | 72-130 | 110 | 29.3 |

| PE-800× 1060 | 640 | 100-200 | 85-143 | 110 | 30 |

| PE-870× 1060 | 660 | 200-260 | 181-210 | 110 | 30.5 |

| PE-900× 1060 | 685 | 230-290 | 100-250 | 110 | 31 |

| PE-900× 1200 | 750 | 95-165 | 87-164 | 110 | 50 |

| PE-1000× 1200 | 850 | 195-265 | 197-214 | 110 | 50.6 |

| PE-1100× 800 | 650 | 50-125 | 38-156 | 132 | 19.86 |

| PE-1200× 1500 | 1000 | 150-300 | 250-500 | 220 | 82.3 |

| PE-1500× 1800 | 1200 | 220-350 | 281-625 | 280 | 122 |

| PE1600× 2100 | 1250 | 175-300 | 870-1500 | 355 | 169 |

| PEV-430× 650 | 360 | 40-100 | 25-75 | 37 | 5.1 |

|---|---|---|---|---|---|

| PEV-500× 900 | 425 | 50-100 | 31.25-68.75 | 55 | 10 |

| PEV-600× 900 | 500 | 70-130 | 53-106 | 75 | 13 |

| PEV-750× 1060 | 630 | 80-140 | 72-140 | 110 | 24.2 |

| PEX-100× 600 | 80 | 7-21 | 2-8 | 7.5 | 0.9 |

|---|---|---|---|---|---|

| PEX-150× 750 | 120 | 18-48 | 5-16 | 15 | 3.5 |

| PEX-200× 1000 | 160 | 20-55 | 6.9-23.8 | 22 | 6.5 |

| PEX-250× 750 | 210 | 25-60 | 8-22 | 22 | 5.1 |

| PEX-250× 1000 | 210 | 25-60 | 10-32 | 30 | 6.5 |

| PEX-250× 1200 | 210 | 25-60 | 13-38 | 37 | 7.7 |

| PEX-300× 1300 | 250 | 20-90 | 10-65 | 75 | 11.6 |